The full name of

this system is a Deep-cold ethanol system or low-temperature ethanol system, it’s

divided into two parts, one is the extraction part and another is the

concentration part.

The full name of this system is a Deep-cold ethanol system or low-temperature ethanol system, it’s divided into two parts, one is the extraction part and another is the concentration part.

The extraction part also can be divided into

two parts, one is the cooling system and another is the extraction system.

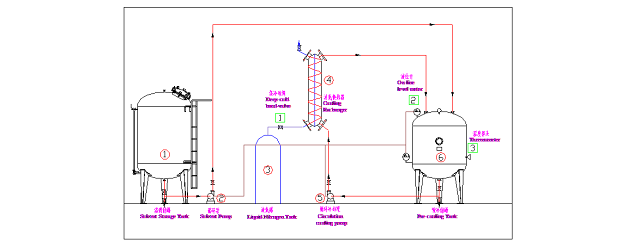

Cooling system

1. Solvent storage tank

2. solvent pump

3. liquid nitrogen tank

4. Cooling exchanger

5.

Circulation

cooling pump

6.

Pre-cooling

tank

What’s that and

How does it work?

Cooling is a step before the extraction and is important for the whole system, It’s the key point of this technique, because the cooling temperature needs to be below -70 degrees.

1.

Start the Solvent Pump to flow the 95%

ethanol to the Pre-cooling Tank from the Solvent Storage Tank. On censoring the

real level value of ethanol in the Pre-cooling Tank reaches the Top-Limit set,

the Solvent Pump will stop automatically.

2.

Start the Circulation Cooling Pump to let

the 95% ethanol flow in circulation between the Pro-cooling Tank and the

Cooling Exchanger.

3.

First, open the valve which is on the Liquid

Nitrogen Tank and controls the liquid nitrogen outlet

Then, open the valve which is connected to the Cooling Exchanger and

with a long hand bar. Soon after this valve is opened, the liquid nitrogen will

come into the exchanger and in the process of becoming vapor. At the same time, you

will find a vapor or smoke coming out from the top of the exchanger, this is

the nitrogen gas.

4.

On censoring the real temperature value of

ethanol in the Pre-cooling Tank reaches the target value set, the Circulation The cooling Pump will stop automatically.

One batch of pre-cooling work ends, the solvent is

ready for putting into the extractor.

Extraction

devices

What’s that and

how does it work?

The left tank in the photo is the Extraction tank, it's jacket tank, the cooled ethanol will be pumped in the tank and the jacket, then we input the biomass from the top feed port and soak it with frozen ethanol and the extraction tank is equipped with a stirrer, so the biomass and chilled ethanol also will be mixed and stirred. This extraction also equipped with Pneumatic discharging door. When the extraction completed, control the air compressor, the pneumatic door will be opened to discharge the used biomass;

Two filters are in the middle of the picture, the filtration accuracy of the filter can be adjusted by customers’ requirements. Usually the filtration accuracy is 40 mesh;

The right tank is

the Extract

liquid storage tank stores the extracted liquid here and waiting for

concentration, that means the extraction process in completed.